In the vast world of textile materials, nylon rib twill Oxford cloth has become the preferred material in many industries with its unique weaving process and excellent performance.

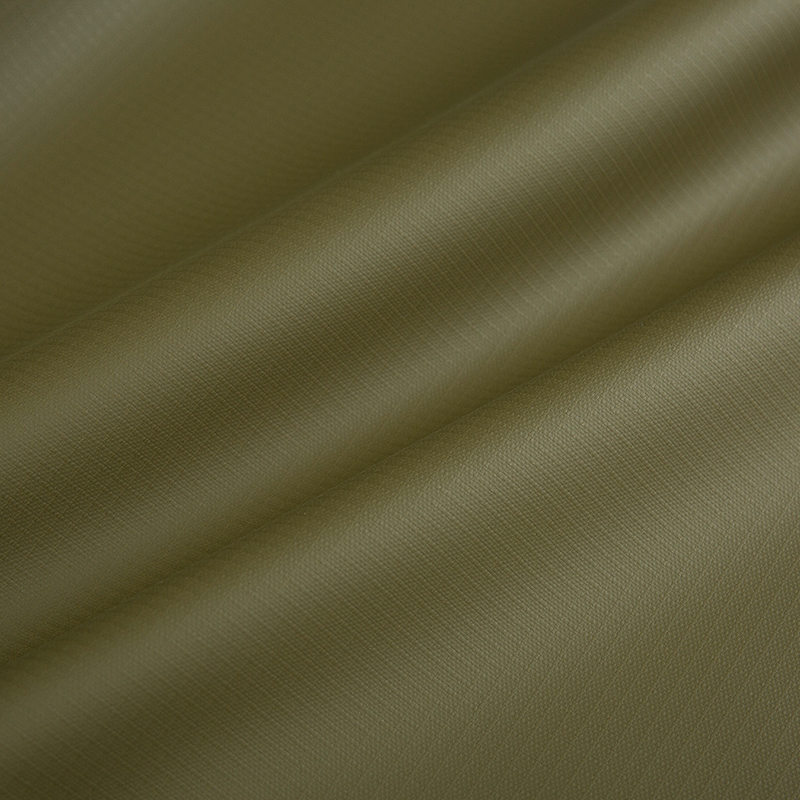

In the field of textiles, twill weaving and plain weaving are two basic weaving methods. Compared with plain weaving, where the warp and weft are vertically interwoven at a ratio of 1:1, the warp and weft interweaving points of twill weaving present a certain tilt angle. This structural difference makes twill Oxford cloth show unique characteristics in performance, especially the improvement of its elasticity and tear resistance, which gives the fabric a wider application potential.

Tilted interweaving of warp and weft: In twill weaving, the interweaving points of warp and weft are no longer limited to the vertical direction, but form a certain tilt angle. The existence of this tilt angle enables the fabric to better disperse stress when it is subjected to force, reduce the situation of local concentrated force, and thus improve the overall strength and tear resistance of the fabric.

Improved elasticity and tear resistance: Due to the tilted interweaving of warp and weft, twill Oxford cloth shows better elasticity in the warp and weft directions. This elasticity not only makes the fabric fit the human body or the surface of the object better during wearing or use, but also absorbs and disperses energy through elastic deformation when impacted by external forces, thereby protecting the fabric itself from damage. At the same time, the twill structure can effectively prevent the fabric from expanding rapidly in the same direction during the tearing process, further improving its tear resistance.

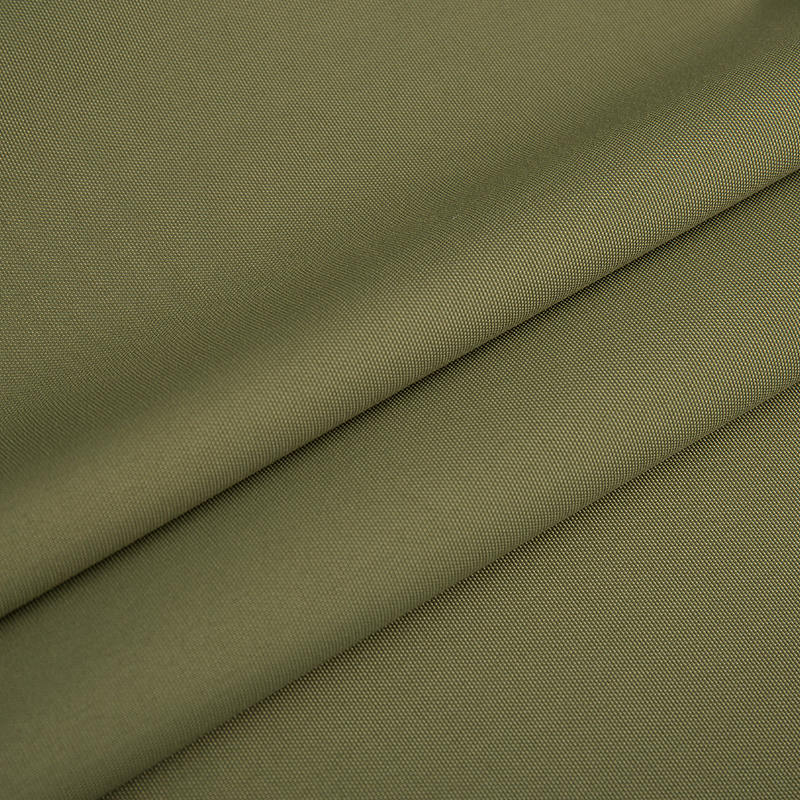

As a high-performance synthetic fiber, nylon is well-known for its high strength, wear resistance, and corrosion resistance. The nylon rib twill Oxford cloth formed by combining nylon with twill weaving not only inherits the excellent properties of nylon fiber, but also further improves the overall performance of the fabric through the twill structure.

High strength and wear resistance: Nylon fiber itself has high strength and wear resistance, which enables the nylon rib twill Oxford cloth to maintain structural stability and integrity when subjected to large tension and impact. At the same time, the twill structure can effectively disperse external forces and reduce the wear of the fabric when it is under force, thereby extending its service life.

Excellent elasticity: Twill weaving gives nylon rib twill Oxford cloth better elasticity, which makes the fabric fit the human body or the surface of the object better during wearing or using, improving comfort and use efficiency. At the same time, elastic deformation can also absorb and disperse external force impact, protecting the fabric itself from damage.

Wide range of applications: With its high strength, wear resistance, corrosion resistance and excellent elasticity, nylon rib twill Oxford cloth has been widely used in many fields. In the field of outdoor products, such as tents, backpacks, assault jackets, etc., nylon rib twill Oxford cloth has become the first choice for outdoor explorers due to its good waterproof and tear resistance. In the field of transportation, such as car seat covers, luggage linings, etc., nylon rib twill Oxford cloth provides passengers with a more comfortable and convenient riding environment with its wear resistance and easy cleaning characteristics. In addition, in the fields of military equipment, industrial protection, etc., nylon rib twill Oxford cloth has also demonstrated its excellent performance and broad application prospects.

In the production process of nylon rib twill Oxford cloth, the fabric performance can be customized by adjusting the density, tension of the warp and weft, and the specifications and types of the fibers. This customized production method enables nylon rib twill Oxford cloth to meet the diverse needs of different fields and different uses.

Adjustment of warp and weft density: The density of the warp and weft directly determines the tightness and weight of the fabric. By increasing the density of the warp and weft, a thicker and more wear-resistant nylon rib twill Oxford cloth can be produced; conversely, a thin and soft fabric can be obtained. This density adjustment enables nylon rib twill Oxford cloth to show more flexible and adaptable performance when dealing with different environments and conditions.

Adjustment of tension and fiber specifications: The adjustment of tension affects the elasticity and shape stability of the fabric. By reasonably controlling the tension, nylon rib twill Oxford cloth that is both elastic and not easy to deform can be produced. At the same time, the adjustment of fiber specifications, such as fiber thickness and length, can also have a significant impact on the performance of the fabric. For example, the use of fine fibers can produce softer and more delicate fabrics; while the use of coarse fibers can improve the strength and wear resistance of fabrics.

With the advancement of science and technology and the development of the industry, the performance and application areas of nylon rib twill Oxford cloth are also constantly expanding and deepening. In the future, we look forward to seeing the introduction of more innovative technologies and materials to further enhance the performance and sustainability of nylon rib twill Oxford cloth. Faced with increasingly diverse market demands and consumer preferences, customized production and personalized design will also become an important direction for the development of nylon rib twill Oxford cloth. In this process, we must not only pay attention to the performance improvement and application expansion of fabrics, but also pay attention to environmental protection and sustainable development, and jointly promote the green transformation and sustainable development of the textile industry.

With its unique weaving process and excellent performance, nylon rib twill Oxford cloth has demonstrated extensive application potential and value in many fields. In the future, with the continuous advancement of technology and the continuous development of the market, we have reason to believe that nylon rib twill Oxford cloth will play its unique advantages in more fields and bring more convenience and beauty to human life and work.